Based on performance and specific needs, printers vary in cost. Alternative to expensive modeling, it comes into play as 3D printers that create desired images. Currently, it is used to make models and prototypes like jewelry, tools, furniture, and other items. Moreover, it saves the user time and money as they work faster than normal printers. Wondering how much a 3d printer costs? Find out below:

4 Types of 3d Printers

Average 3D printer

The average 3d printer requires a lot of time assembling, testing, and measuring before printing. It is a bit fast and can print a few different things. Moreover, printers in this category are not designed to run the required time until you make adjustments that keep them running. The average 3d printer costs 500$ to 1400$. Also, it is good for school purposes.

Best 3d Printers Under 1000

Industrial or FDM

The industrial 3D printer has a very smooth connection with a solid construction as well suited to making a quick prototype of mechanical parts. Achieve high quality through the mechanical polishing printing process with a fair accuracy rate. Industrial 3d printers are somewhat expensive as 20K$ to 100K$ because they use melting bases to reduce some of the wide range of thermoplastics engineering that can only be affordable for business purposes

High-end 3D printer or SLS

High-end printers, also known as SLS, print various materials using a powerful laser to immerse small polymer powder particles into a solid structure. Moreover, it is ideal for undercuts, small walls, and interior elements. Now you may wonder how much a high-end 3d printer costs. Due to mechanical properties, neither high nor cheap prices vary from 4K$ to 20K$.

Large or SLA printer

SLA printer is still one of the most popular technologies because it uses a laser photopolymerization process. For smooth finishing, consider SLA best known for its ability to produce high-precision, isotropic, and watertight prototypes. Furthermore, between 100$ and 500$, you can use it for purposes like manufacturing, dental, jewelry, modeling, and education.

[acf field=”table”]3D Printers Cost – Comparison Table

| Types | Uses | Composition | Ranges | Want to Buy? |

|---|---|---|---|---|

| Average | Local or school, the photopolymerization | UV laser | 500$ to 1400$ | |

| Industrial or FDM | Mechanical polishing printing | ABS, Polycarbonate, and ULTEM | 20K$ to 100K$ | |

| High-end or SLS | Undercuts and interior | Laser | 4K$ to 20K$ | |

| Large or SLA | Modeling and other designs | Light-reactive thermoset | 100$ to 500$ |

Application of 3D Printers

Audiology

Hearing professionals and earmold labs use the digital flow of 3D printing to create custom high-quality ear products with high volume in programs such as behind-the-ear hearing aids, hearing protection, and custom earplugs and earbuds.

Entertainment

High-definition material models are widely used in recording, portraying Realistic sculptures of the characters, and making Templates. The 3D printed parts are starred in motion pictures, video games, and special effects of blockbuster movies.

3D Printer for Miniatures

Product Design

Performing rapid prototyping with 3D printing empowers engineers and designers to turn ideas into real-time proofs, further these ideas into reliable images that look and work as final products, and direct products to a series of verification stages in mass production.

Education

3D printers are tools with advanced research. They encourage creativity and expose students to professional-level technology while supporting the curriculum across science, art, engineering, and design.

How does a 3D printer build and work?

3D printing is part of the family of additional production and uses the same techniques as traditional inkjet printers- albeit in 3D. It takes a combination of advanced software, materials such as powder, and precise tools to create a three-dimensional object from scratch.

3D printers function as:

Modeling

As a dentist, modeling software is very important in the industry, where labs use three-dimensional software to design teeth that fit exactly the individual. It is also important in the space industry, where they use software to design some of the most complex parts of rocketships.

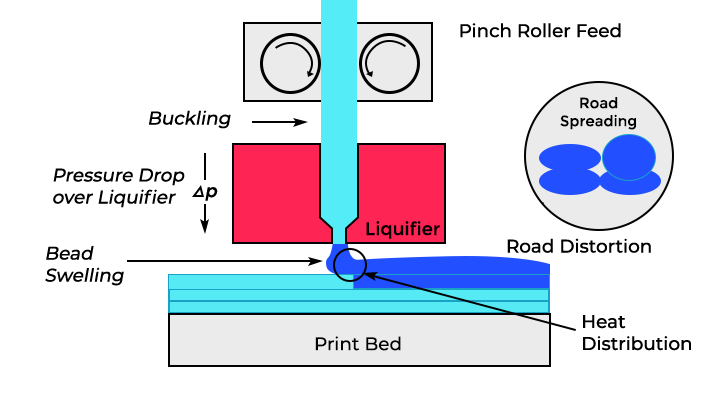

Cutting

The cutting software scans each model layer and tells the printer how to re-create that layer. The cutters also tell the 3D printers to “complete” the model and help shape and strengthen the object.

Printing

Once the 3D modeling and cutting are complete, it is time for the 3D printer to take over finally. The printer usually does the same thing as a traditional inkjet printer in a straightforward 3D printing process. The nozzle goes back and forth while removing wax or plastic-like polymer layer-by-layer, waiting for that layer to dry adding the next level. Add hundreds through thousands of 2D prints to make something three-dimensional on top of each other.

[acf field=”faq”]How Much Does a 3D Printer Cost – FAQs

Q: How much does a building house for a 3D printer cost?

A: The 3D printing system promises to build houses faster, cheaper, and more accurately with fewer people. 3D printers claim that their printing materials will be more durable and stronger than most traditional building materials. The average cost of 3D printers is about $ 25K per kilogram for quality providers.

Q: What is the major difference between 3D vs. 2D printers?

A: The difference is that of printing compared to production. A 2D printer is a process of putting a picture on paper. The 3D printer will create the image we have been given, including plastic materials.

Q: Does a 3d printer need software?

A: Once you have access to the 3D model, you will need software to run the printer. You can use blender software to create sophisticated 3D models, design, and edit.

Q: How long is it required for 3D printing?

A: 3D printing depends upon size, geometry, and printing technology. The segmentation takes 30 minutes to 7 days approximately or maybe more.

Q: Does a 3D printer use ink?

A: Traditional 3D printers use powdered metals and plastics as their ink. These are great for making very strong metal or even synthetic bones.